Weld Crack

Weld crack

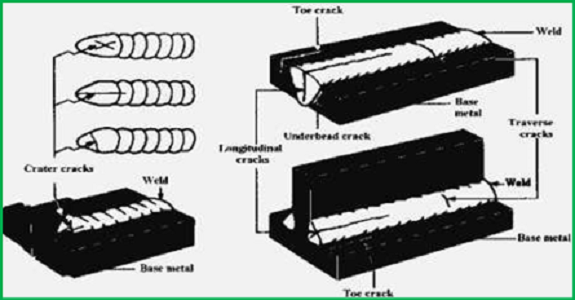

1.1. Cracking:

If a weld crack is found, it must be removed and magnetic-particle inspection performed to ensure every point has been removed before re-welding. Weld Crack can occur on top of a weld bead, within the weld, or in the base metal.

GMAW electrode wires are low hydrogen in content and have no flux coating to attract moisture, can help avoid cracking in the weld and heat-affected zones, if kept clean and dry. Spools or reels must be free of moisture both while being used and when being stored.

A crack can easily occur on welding of aluminum, due to metal contraction as the weld pool cools, while the base metal remains hot. Cracks may be more numerous with aluminum, but they may also occur in stainless steel and galvanized materials.

Cracks may occur if excess heat input is used for the particular thickness of material being welded, or steels with high carbon content, over 30 %, are likely to crack due to their hardness.

Spatter:

If there is a lot of spatter resulting from a weld, other problems could be occurring, possibly causing a weld defect. Low voltage or high wire feed speeds, could also be the cause of a weld defect such as incomplete fusion. Many electrode manufacturers prepare their electrode wires with various alloys and coatings to help provide less spatter.

Dirt or rust on the electrode wire can also be a cause for excess weld spatter, as well as dirt or rust on the base metal. The considerations are:

- The shielding gas selected in a particular situation can cause spatter. CO2 shielding gas is generally considered to yield more spatter in mild steel than a mixture of Argon + CO2, or a mixture of Argon + O2 for spray arc welding.

- The gas flow rate, set on the regulator/flowmeter, should also be considered. Excessive gas flow rates can cause a turbulent, unstable arc, which also can cause spatter.

- Spatter can also form on the gun nozzle and contact tube blocking, gas flow and improper volt- amp (WFS) parameters can also cause problems. Certain compounds are available to apply to nozzles so that spatter will not adhere as easily.

- If a drag or push angle is being used, too much of an angle can lead to spatter, because the arc is not properly directed below the nozzle, as it would be with a proper angle, 5-10 degrees.

- Too much electrode extension, can also cause spatter due inadequate shielding gas, as well, improper melting of the electrode, due to the longer preheating time for the electrode wire.

- Too fast of a travel speed can also cause spatter because the molten metal deposited is not given enough time to properly wet out.

Arc Strikes:

Arc strikes happen when the welding electrode comes into contact with the base metal outside of the final weld. Arc strikes result in heating and very rapid cooling. Arc strikes may result in hardening or fatigue cracking, and serve as potential sites for fracture initiation.

Arc strikes should be removed by grinding to a depth of 1/8 inch below the original surface removing all traces of arc strikes and their hardened heat-affected zones.

However, in tension areas, the locations where arc strikes were removed, should have Magnetic- Particle inspection and hardness testing performed per AWS D1.5 Welding Code.

we provide standard specifications for welding procedures for all welding process and Brazing. We offer Welder Procedure Specification, Welder Certificate Renewal Process, Procedure Qualification Record, Welder Qualification Testing, welder Training and Welder qualification services in Coimbatore,Trichy, Salem, Erode, Chennai.

Please feel free to reach us https://aqcinspection.com/training/ to learn more about any of the methods in detail.

Visit our technical and career updates at our Blog site https://advancedqualitycentre.blogspot.com . or

Comments

Post a Comment