Acceptance Criteria for Liquid Penetrant Testing -LPT

Acceptance Criteria for Liquid Penetrant Testing -LPT as per ASME , AWS and API standards

Liquid penetrant testing simply called as PT. Sometimes Dye Penetrant Testing is a surface defect detection NDT method and is more sensitive to all kind of surface defects, such as cracks , porosity, hot tears, laps, etc.

The NDT methods are trained by NDT Training Institutes with their NDT courses, and the LPT is one among the basic Non Destructive Testing Methods.

Various international standards for Liquid Penetrant Testing are as below

ASME Boiler and Pressure Vessel Code BPVC- Section V – Article 6 and Article 24

ASTM E-1417 (ASTM Standard)

ASTM E-165 (Penetrant Testing Standard for general Industry ASTM Standard)

ISO 3452-1 (ISO Standard)

SAE AMS 2644 (Aerospace Standard)

AS 2062 (Australian Standard )

DIN EN 571

The Indications are evaluated as per Clients Acceptance Criteria or the Product Standard in conformance with the clients acknowledgement .

Few examples of product standards are as below :

AWS D1.1 – Structural Steel Welding Standards

API 1104 – Pipeline Welding

ASME BPVC section VIII – Pressure Vessel

ASME B 31.1 – Process Piping

ASME B 31.3 – Power Piping

ASME B16.34 – Valves, and lot more

Acceptance Criteria for Liquid Penetrant Testing -LPT from the above mentioned standards are given below for your convenience.

DYE PENETRANT INSPECTION – API 1104

Rejection Criteria

Liner Indications

Indications > 1/16” (1.59mm) shall be considered as Relevant Indication, Relevant indications are rejectable if:

Evaluated as crater cracks or star cracks and > 5/32” (3.96mm) in length.

Evaluated as cracks other than crater cracks or star cracks.

Evaluated as IF and >1” (25.4mm) in total length in a continuous 12” (304.8 mm) weld or >8% of the weld length.

Rounded Indications:

For evaluation, the maximum dimension of rounded indications shall be considered as it size. Indications are reject able as defects if:

Individual indication > 1/8” (3.17mm)

Distribution of scattered rounded indications exceed concentration API 1104 fig. 18 or 19.

Clustered rounded indications > 1/2” (12.7mm)

Combined length of clustered indications > 1/2” in any 12” (304.8mm) weld.

Any individual indication in a cluster > 1/16” (1.59mm).

DYE PENETRANT INSPECTION – ANSI/ASME B31.1

Liner indication:

Any crack or liner indication.

Rounded indications:

Indications is dimensions > 3/16” (5.0mm).

Four or more rounded indication in a line separated by 1/16” (2.0mm) or less edge to edge.

Ten or more rounded indication in any 6 sq. in. (3870mm2) of surface with the major dimension of this area not to exceed 6 in. (150mm).

DYE PENETRANT INSPECTION – ANSI/ASME B31.3

Liner indications:

Any cracks or linear indications.

Rounded indications:

Pending verification from ANSI. Until otherwise stipulated by ANSI B31 Committee, apply B31.1 criteria for rounded indications.

DYE PENETRANT INSPECTION – ASME Section VIII Div. 1

Relevant linear indication >1/16” (1.59mm)

Relevant rounded indications >3/16: (4.77mm)

Four or more rounded indications in a line separated by 1/16” (1.59mm) or less (edge to edge)

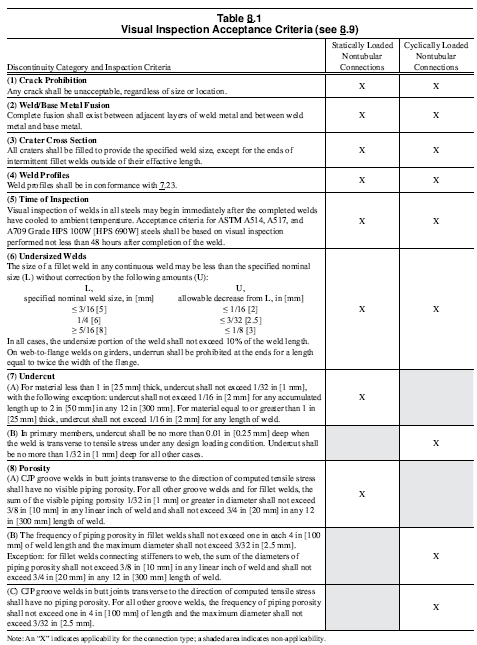

DYE PENETRANT INSPECTION – AWS D1.1

Refer the table below from AWS D1.1 , for the acceptance criteria for Liquid Penetrant Testing, the acceptance criteria for visual testing also applies for Liquid / Dye penetrant testing as per AWS D1.1 .

This method is applicable in almost all material except for material with porous surface, it is suitable for both casting/raw material and welding inspection.

For more details ping me at watsapp number 8668082413 or visit https://aqcinspection.com/training/.

Remember Penetrant Testing is an low cost and more easily adaptable method for all kinds of industry, but without proper training and certification for specific NDT method the PT test is not reliable.

NDT courses are readily available in training institutes in all major cities around the world to train this simple testing method.

Visit our technical and career updates at our Blog site https://advancedqualitycentre.blogspot.com . or https://ndtcenter.blogspot.com

Non Destructive Testing Certification

ReplyDeleteFind the right instructor for you. Choose from many topics, skill levels, and languages. Join millions of learners from around the world .join now for more guidance - https://www.uptti.com/non-destructive-testing-training-courses/