Dissimilar metal in TIG Welding process

Why use this TIG welding process:

TIG Tungsten Inert Gas otherwise called as GTAW- Gas Tungsten Arc Welding , Involves melting the metal using the arc created by tungsten electrode,

The welding can be done with or without filler metal,

Argon Gas is used as shielding around the weld area, to shield the weld from atmospheric gases.

As an inert gas is used for shielding the weld, the quality of weld is good without any Slag inclusions and good weld profile.

TIG welding is selected to receive a high quality welds for analysis purposes

Where we use dissimilar metals ?

Dissimilar metals are used in process pipe line industry, heat exchangers, boilers and Structural steel fabrication industry.

SS 304/ SS316 (Austenitic Stainless Steel )

ASTM A -210 (Medium Carbon Steel)

ASTM A-36 (Low Carbon Steel )

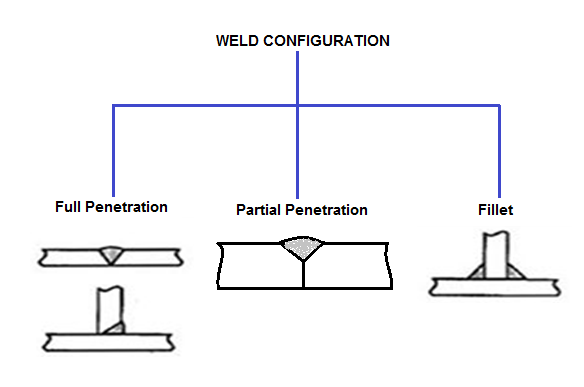

Types of Weld Joint :

Butt Joint, T Joint, Lap Joint , Corner Joint, Edge Joint

Types of Joint Configuration:

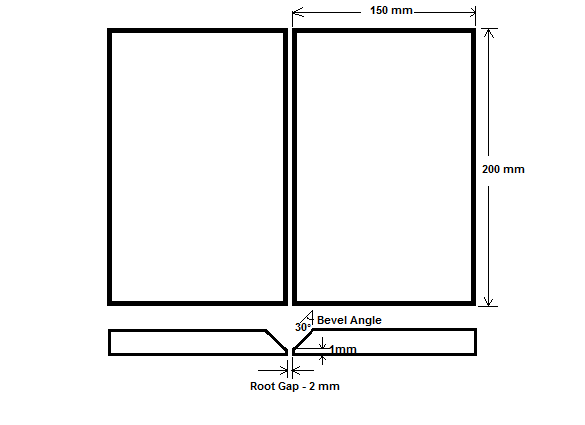

Joint Design:

Why we use Butt Joints

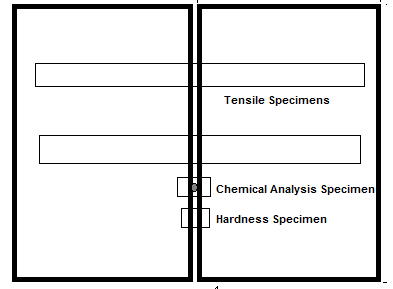

To carry out the study of difference in mechanical properties of weld between different metals, the below tests are to be carried out

- Tensile Test ( for Yield Strength, Tensile Strength, % of Elongation, % of Reduction)

- Chemical Analysis

- Hardness Test

In order to carry out a tensile test a Full penetration butt weld is required.

Why we use Dissimilar metal in TIG Welding?

TIG Welding is a versatile welding process, which can be used for high quality welding,

Dissimilar Welds are made due to a design requirement , the joining of two metals with different chemical properties.

Dissimilar weld can also be made with Shielded Metal Arc Welding (SMAW), Submerged Arc Welding (SAW), and many other processes.

Which Filler Metal is used ?

| Base metal Grades | Description | Electrode Used |

| SS304 to SS 304 | SS to SS | SS 308 |

| SS 304 to ASTM A201 | SS to Medium Carbon Steel | SS 309 |

| SS 304 to ASTM A 36 | SS to Low Carbon Steel | SS 309 |

Electrode: As a common the Electrode used in TIG welding is Tungsten used because of its high melting temperature, the fusing metal is supplied additional as filler metal.

SS 308 Filler metal is used for SS to SS weld because of its similar chemical and mechanical property.

SS 309 Filler metal is used for SS to MS weld because of its higher Ferrite content, which will reduce weld dilution and avoid weld cracking .

we provide standard specifications for welding procedures for all welding process and Brazing. We offer Welder Procedure Specification, Welder Certificate Renewal Process, Procedure Qualification Record, Welder Qualification Testing, welder Training and Welder qualification services in Coimbatore,Trichy, Salem, Erode, Chennai.

Please feel free to reach us https://aqcinspection.com/training/ to learn more about any of the methods in detail.

Visit our technical and career updates at our Blog site https://advancedqualitycentre.blogspot.com . or

We Specialize In World-Class Welding Courses And Trainings . Call Us Today To Get Started! Our Welding Classes Feature Hands-On Training And Vary From Beginner To Get your career started on the right path with welding training.

ReplyDelete