Welding of Stainless Steels

Welding of Stainless Steels:

General Concepts:

Stainless steels, resumed here in a general way, are defined as steel alloys, where the chromium content ranges from 10.5% to 30%. There are five distinct types of stainless steel:

Ferritic stainless steel:

Contains from 10.5 to 30% chromium, is low in carbon, with some alloys containing major amounts of molybdenum, columbium and titanium.

Austenitic stainless steel:

Contains from 16% to 26% chromium and up to 35% nickel and have very low carbon content. Some of these steels are also alloyed with a minor amount of molybdenum, columbium and titanium.

Martensitic alloy steel:

Contains from 12% to 17% chromium and up to 4% nickel and 0.1% to 1.0% carbon. Some alloys will also have minor additions of molybdenum, vanadium, columbium, aluminum and copper.

Duplex stainless alloys:

Contain 18% to 28% chromium, 2.5% to 7.5% nickel and low carbon contents. Some of the alloys will also have additions of nitrogen, molybdenum and copper.

2. Welding Processes:

All stainless steels are commonly welded by SMAW, GMAW, FCAW, and SAW processes. GTAW is also commonly used, but it is a slow process. The most used process is SMAW because the equipment is portable and easy to use.

Processes by GMAW, FCAW, and SAW are being used more often because they are economical and produce high quality welds. The manufacturers’ recommendations for welding stainless steels include joint designs, preheat temperatures, associated post-weld heat treatment and shielding gas.

3. Joint design:

Weld joints are prepared by plasma-arc cutting, machining or grinding, depending on the alloy. Before welding, the joint surfaces must be cleaned of all foreign material, such as paint, dirt, scale, or oxides.

Cleaning may be done with suitable solvents and light grinding. Care should be taken to avoid nicking or gouging the joint surface since such flaws can interfere with the welding operation.

4. Passivation of Stainless Steels:

The Welding Inspector should understand the meaning of stainless steels passivation. Passivation is a post-fabrication cleaning method of maximizing the inherent corrosion resistance of stainless steels. It is not a scale removal treatment, nor is it like a coat of paint.

The passivation treatment is also designated by “pickling” and is simply the removing iron contamination with nitric acid, citric acid or hydrofluoric acid mixtures. Stainless steels cannot be passivated unless the steel surface is clean and free of scales from welding operations.

Citric acid is a less hazardous method and has environmental benefits in terms of ‘NOx’ fume emission and waste acid disposal. Solution strengths of 4-10% citric acid are specified for passivation treatments in ASTM A967.

The passivation treatment specifications for stainless steels are:

- ASTM A380 – Practice for Cleaning, Descaling and Passivation of Stainless Steel Parts

- ASTM A967 – Specification for Chemical Passivation Treatments for Stainless Steel Parts.

Low and High Alloy Steels:

General Concepts:

Alloy elements are metals such as manganese (Mn), chrome (Cr), nickel (Ni), molybdenum (Mo). Carbon (C) is not an alloy element. Low alloy steels contain 1–5% of alloy elements. High alloy steels contain more than 5% of alloy elements.

2.Welding Processes:

Low and high alloy steels can be welded by SMAW, GMAW, FCAW, and SAW processes. GTAW is also commonly used, but it is a slow process. The most used process is SMAW because the equipment is portable and easy to use.

Heat Resistant Steels:

Heat resistant steels are a low alloy steel, alloyed with a certain percentage of molybdenum (Mo) and sometimes also chromium (Cr). The addition of these alloying elements imparts heat resistant characteristics and the steel retains its strength at high temperatures.

These types of materials can also be welded by SMAW, GMAW, FCAW and SAW processes, commonly used in boiler tubes, boiler plates and high pressure pipes.

AWS D1.1 contains a selection guide to match electrode types with various ASTM and API steels. Recommendations should be followed when developing the welding procedures, heat-treatment and stress-relief for high strength low alloy steels conforming to ASTM A 514, A 517, or A 710.

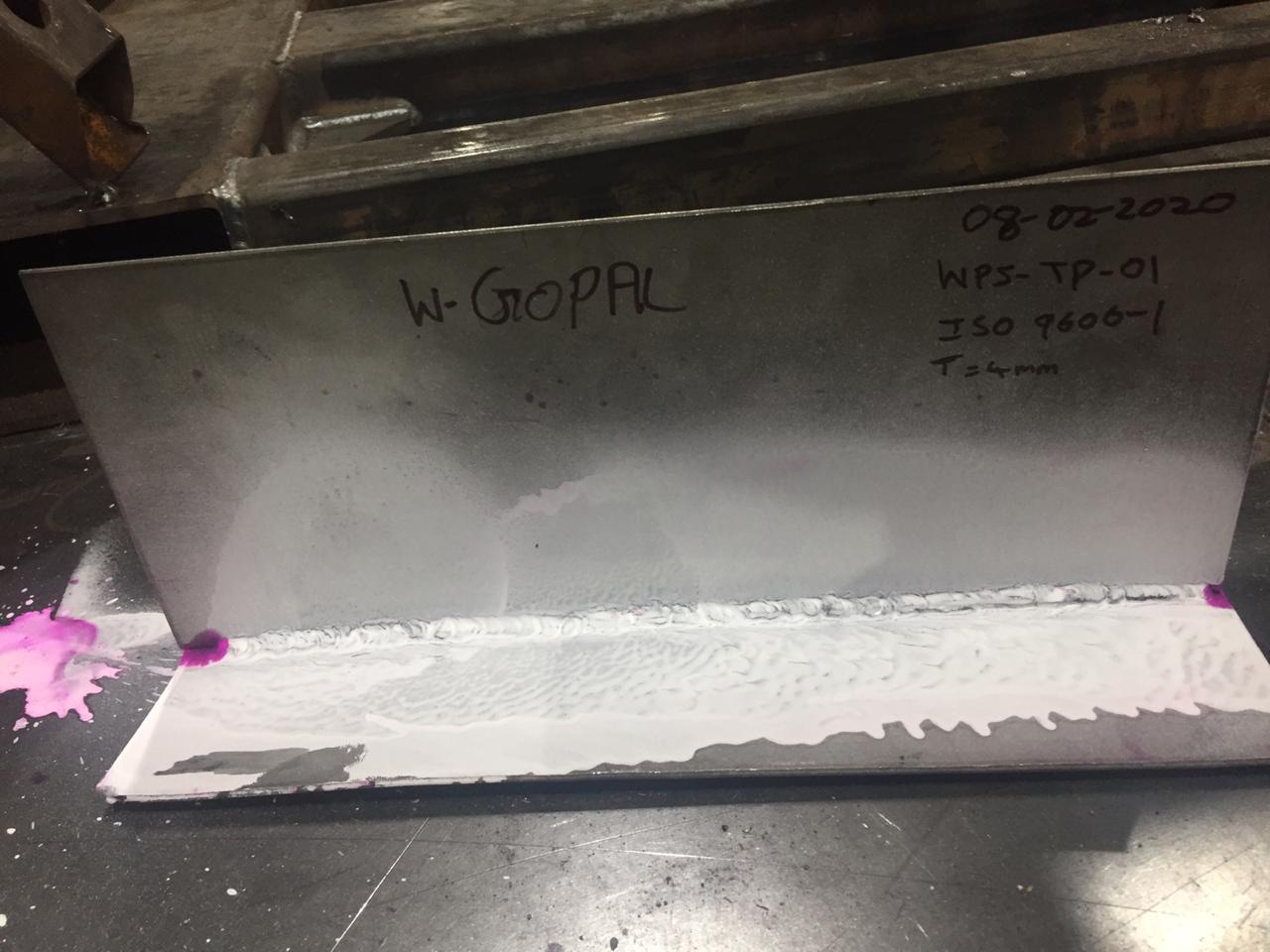

we provide standard specifications for welding procedures for all welding process and Brazing. We offer Welder Procedure Specification, Welder Certificate Renewal Process, Procedure Qualification Record, Welder Qualification Testing, welder Training and Welder qualification services in Coimbatore, Trichy, Salem, Erode, Chennai.

Please feel free to reach us https://aqcinspection.com/training/ to learn more about any of the methods in detail.

Visit our technical and career updates at our Blog site https://advancedqualitycentre.blogspot.com . or

Comments

Post a Comment