NDT – Few Other Methods

Here are some rarely used NDT – Few Other Methods

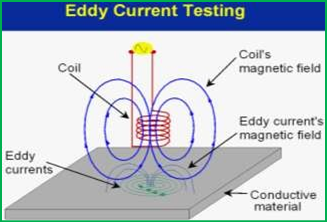

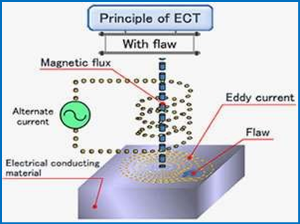

1. Eddy Current Testing – ET:

Eddy-current inspection uses electromagnetic induction to detect flaws in conductive materials. A circular coil carrying current is placed in proximity to the test specimen (electrically conductive). The alternating current in the coil generates changing magnetic field which interacts with test specimen and generates eddy current.

The term eddy current (also called Foucault currents) comes from analogous currents seen in water where localized areas of turbulence known as eddies give rise to persistent vortices. When alternating current is applied to the conductor, such as copper wire, a magnetic field develops in and around the conductor.

Variations in the electrical conductivity or magnetic permeability of the test object, or the presence of any flaws, will cause a change in eddy current.

A corresponding change in the phase and amplitude of the measured current. This is the basis of standard (flat coil) eddy current inspection.

There are several limitations, among them: only conductive materials can be tested, the surface of the material must be accessible, the finish of the material may cause bad readings, the depth of penetration into the material is limited, and flaws that lie parallel to the probe may be undetectable.

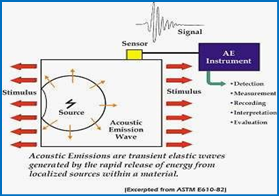

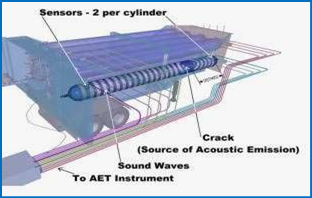

2. Acoustic Emission Testing – AET:

Acoustic Emission Testing (AET) unlike most other nondestructive testing (NDT) is not used commonly.

AET simply listens for the energy released by the object or basically detect acoustic waves generated by sudden movement in solid materials. However, can also detect sources as small as from a pinhole leak or as large as brittle crack advance.

AE tests are often performed on structures while in operation, as this provides adequate loading for propagating defects and triggering acoustic emissions.

3. Phased Array Ultrasonics – PA:

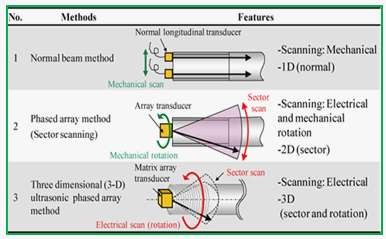

Phased Array Ultrasonics is an advanced method of ultrasonic testing that has applications in medical imaging and nondestructive testing. Common applications are to examine the heart non-invasively or to find flaws in manufactured materials such as welds.

Single-element (non phased array) probes—known technically as monolithic probes, emit a beam in a fixed direction. To test or interrogate a large volume of material, a conventional probe must generally be physically turned or moved to sweep the beam through the area of interest.

Examination by phased array: On the top, probe emits a series of beams to flood the weld with sound. Bottom, the flaw in the weld appears as a red indication on the instrument screen.

The beam is controllable because a phased array probe is made up of multiple small elements, each of which can be pulsed individually at a computer-calculated timing. The term phased refers to the timing, and the term array refers to the multiple elements.

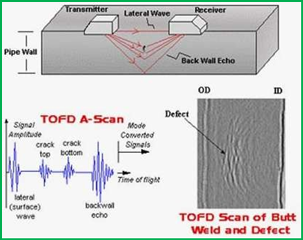

4. Time Of Flight Diffraction (TOFD) Technique:

TOFD was originally intended for sizing of welding flaws which have been detected with other ultrasonic methods. This technique was used in Germany and later it was published that the TOFD technique had also been used for a variety of flaw detections.

In addition, the simplicity of its scanning concept enables application on many different components, including such complex geometries as nozzles and nodes.

Non destructive Testing NDT- few other Methods have different sensitivity level with few changes in them such as the chemical grain sizes, Sound frequency and many other factors. So selection of the factors affecting the sensitivity depends on the size of defects to be found. The size of defects to be found depends on the critical factor and design criteria.

The designer shall decide the maximum size of defect that can be accepted considering the factors, design pressure and design wall thickness along with safety factor .

Or try to call for ‘Best NDT Technicians in Coimbatore’ and ‘Best NDT engineers near me’ to show them the drawing and design factors to select the appropriate NDT methods for finding out the defects, we can help you assisting such services find us in https://aqcinspection.com/non-destructive-testing/ we can train your employees for inspection or send you manpower and equipment for doing the inspections. You can view our blogs on NDT on https://ndtcenter.blogspot.com

Comments

Post a Comment