Welding Standards-Positions for Welding Pipe

Positions for Welding Pipe

For welding pipe in shops, power plants, oil refineries, and chemical plants for crude oil, gasoline, and natural gas, the same basic welding positions described previously are used.

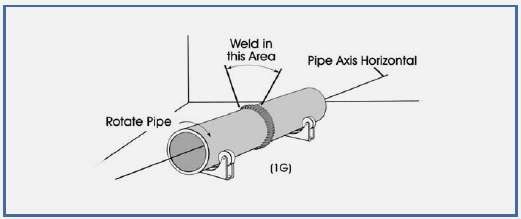

Flat Butt Weld Pipe Position – 1G

A pipe to be welded in the flat position is usually placed on roller dollies or wooden skids. As the pipe is welded, it’s rotated on the dollies or skids. This procedure is the same as the flat position plate welding. The speed of rotation should be the same as the welder’s forward welding speed.

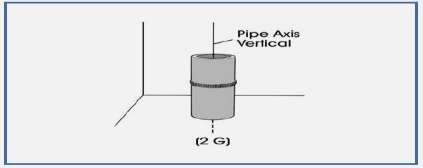

Horizontal Butt Weld Pipe Position – 2G

In this position, the weld around the vertical pipe is the same of a horizontal position plate welding. There is little difference whether the pipe is rotated or fixed because the welding is the same. Either the welder will circle around the joint, or the pipe itself can be turned in a circle if it’s free to rotate.

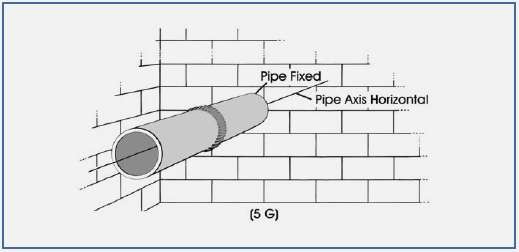

Multiple Butt Weld Pipe Position – 5G

In this position, the axis of the pipe is horizontal, but can’t be rotated. As the welder works around the pipe to make the weld, he or she must weld in a number of different positions.

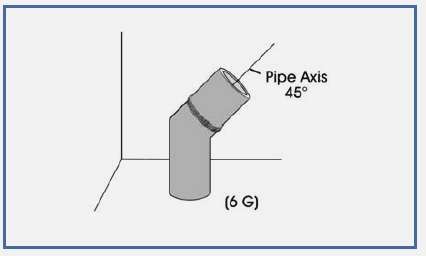

Multiple Butt Weld in Angled Pipe Position – 6G

In this position, the axis of the pipe is at a 45° angle to the horizon. This position is used widely in testing welders’ ability. Therefore, it’s used as an all-position qualification test for pipe welders.

Advanced Quality Centre is an organization which provides many trainings and seminars for sake of individual knowledge growth and industrial growth. For trainings on

- NDT courses

- Welding courses

- inspections courses

- course on Piping

- Tank inspection

- pressure vessel inspection

- Material testing

- QA/QC Courses feel free to contact us at https://aqcinspection.com/training/ .

Free webinars , Online courses are carried out for interested candidates.

Visit our technical and career updates at our Blog site https://advancedqualitycentre.blogspot.com . or

Comments

Post a Comment