Recommendations for Welding

We would see about Recommendations for Welding of Structural Steel as per AWS D1.1 , 2020 revision

Groove Weld: (Clause 4.4.1)

Weld Length : shall be the width of the parts joined , perpendicular to the direction of compressive or tensile stress,

Weld Size: Thickness of thinner part of two joining sections, (with no excess re-enforcement achieved with a improper weld bead)

Partial Penetration Weld :

Weld Thickness: (Clause: 4.4.1.3)

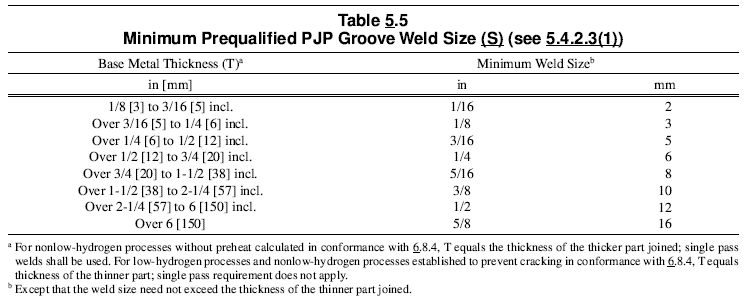

The size of Partial Penetration Groove welds shall be selected from the below table 5.5 based on the thickness ‘ T’ of the joining base metal , Consider the thickness of the thicker part if two different thickness is joined.

Fillet Weld Size.

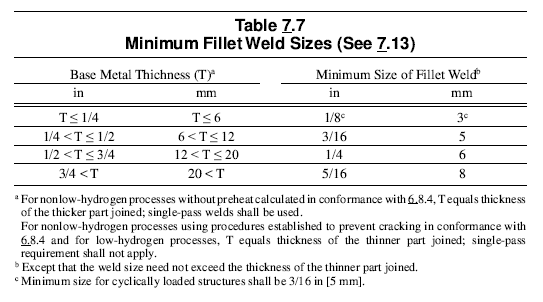

Minimum size of Fillet: (Clause :4.4.2.8)

The minimum Throat thickness of fillet weld shall be selected from table below

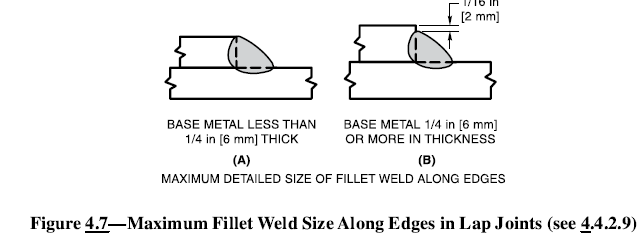

Size of Fillet Weld in Lap Joints:

- For Base Metal Thickness < 6mm , the fillet Leg size = thickness of base metal

- For Base Metal Thickness > 6mm, the Fillet Leg size is 2mm less than the adjacent base metal thickness as shown below

Size of Intermittent Fillet Welds:

Minimum length of Intermittent Fillet Welds: (Clause 4.4.2.4)

Minimum length of Intermittent Fillet Weld shall be > 38mm)

Spacing between intermittent fillet welds: (Clause 4.12.2)

Maximum Spacing between two intermittent/ Stitch weld shall be < 24 x thickness of thinner plate or 300mm whichever is lesser.

Electrode Selection:

The chemical content of Filler metal shall satisfy the minimum requirement of base metal

The tensile strength of the filler metal shall be equel to or greater than the minimum tensile strength of base metal (note: to verify use the MTC of Base metal ad BTC of Filler metal)

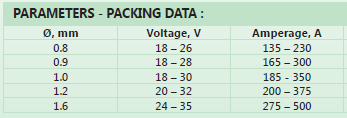

Welding Parameters for GMAW or MAG welding

- Thumb Rule: Electrode Size x 240 A

- Please note the Current Setting greatly depends on the Welding speed of welder, the above data is just a guide line.

Gas Flow Rate:

CO2 : 12-18 Liter Per Minute

80% Argon+ 20% CO2 : 17-22 LPM

Welder Qualification

We are experienced more than a decade in producing the most appropriate procedures for welding. All types of welding Brazing and Soldering process, (WPS / PQR ) and welder qualification , soldering technician qualification & brazing operator qualification.

We have strong client base for WPS approval in India. Welder qualification in Chennai, Welder qualification and WPS approval in Trichy

Please feel free to reach us https://aqcinspection.com/training/ to learn more about any of the methods in detail.

Visit our technical and career updates at our Blog site https://advancedqualitycentre.blogspot.com . or

Comments

Post a Comment