Weld Position- Fillet Welds

Fillet Weld Positions

The advantage of the fillet-welded joint is that it’s unnecessary to prepare the edges of the plates or sheets for welding. Double fillet-welded joints are an improvement over single-fillet joints because they can withstand loads from more than one direction.

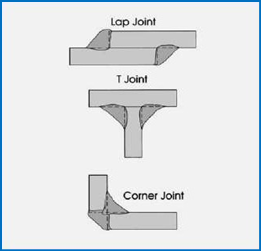

Three of the five basic types of joints – the lap, the T-joint and the corner joint – can be joined with fillet welds.

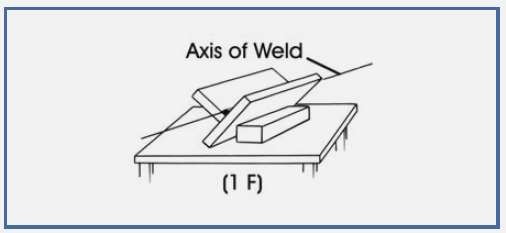

Flat Fillet Weld Position – 1F

The axis of the flat position fillet weld is either horizontal or inclined not more than 15° to the horizontal. The surfaces of the plates are each inclined at about 45° to the horizontal. The face of the weld is on top.

The typical flat-position fillet weld is similar to the flat-position groove weld. The difference is in the positions of the plates forming the joint.

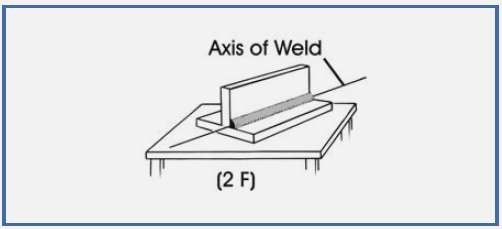

Horizontal Fillet Weld Position – 2F

In this position, both the axis of the weld and the lower plate of the joint assembly are horizontal. For the T-joints and inside corner joints, the other plate is vertical. For lap and outside corner joints, only the edge of the other member is vertical.

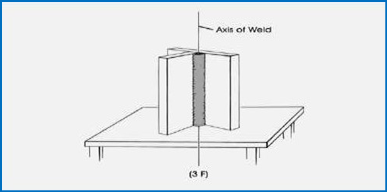

Vertical Fillet Weld Position – 3F

The plates and the axis of the fillet weld are perpendicular to the bench top. Vertical fillet welding is a difficult operation requiring a high degree of skill.

Vertical fillet welds may be deposited by progressing from the bottom up or from the top down. When the welding progresses upward, the metal deposited helps hold the molten metal in place.

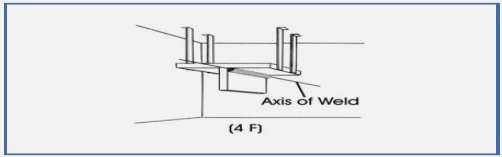

Overhead Fillet Weld Position – 4F

Overhead position fillet welds are basically horizontal-position fillet welds turned upside down. The axis of the weld is horizontal, and the plates are usually vertical and horizontal. This is another difficult welding position because there’s nothing to hold the molten metal against the force of gravity.

Please feel free to reach us https://aqcinspection.com/training/ to learn more about any of the methods in detail.

Welder Qualification

We are experienced more than a decade in producing the most appropriate procedures for welding. All types of welding Brazing and Soldering process, (WPS / PQR ) and welder qualification , soldering technician qualification & brazing operator qualification.

We have strong client base for WPS approval in India. Welder qualification in Chennai, Welder qualification and WPS approval in Trichy , Welder certificate in Pondichery, Salem, Kadaloor, Bangalore,

Hosur, Kerala, Erode, and also expertise NDT and Welding Trainings.

Visit our technical and career updates at our Blog site https://advancedqualitycentre.blogspot.com . or

Comments

Post a Comment