Equipments and materials for NDT lab set up

Equipments and materials for NDT lab set up

Radiography Testing:

1) X-Ray tube head -450 kV capacity ( only if construction of a exposure room with approval from government is possible)

2) RT Films (D4 )

3) lead screen 0.125mm, 0.25 mm

4) Film casettes

5) set of IQI -wire type and hole type, ASTM standards and ISO standard,

6) Lead letters , alphabets and numbers

7) RT weld Film viewers (with intensity control )

8) Set of developed films

9) Film Densitometer

10 ) Dark room set up for developing, with seperate tenks for Developer, Stoper, Fixer & Rinsing ( only if required)

Computed Radiography:

Phosphor plate with lead screens and casette

CR Scanner and Computer

Digital Radiography:

- Requires a Fixed Digital Radiography Machine

- Inbuilt X-Ray tube of capacity 150kV upto 400 kV

- Inbuilt sample positioning system

- Flat panel detector

External control console - Computer.

( There are local manufacturers for Digital XRay machine )

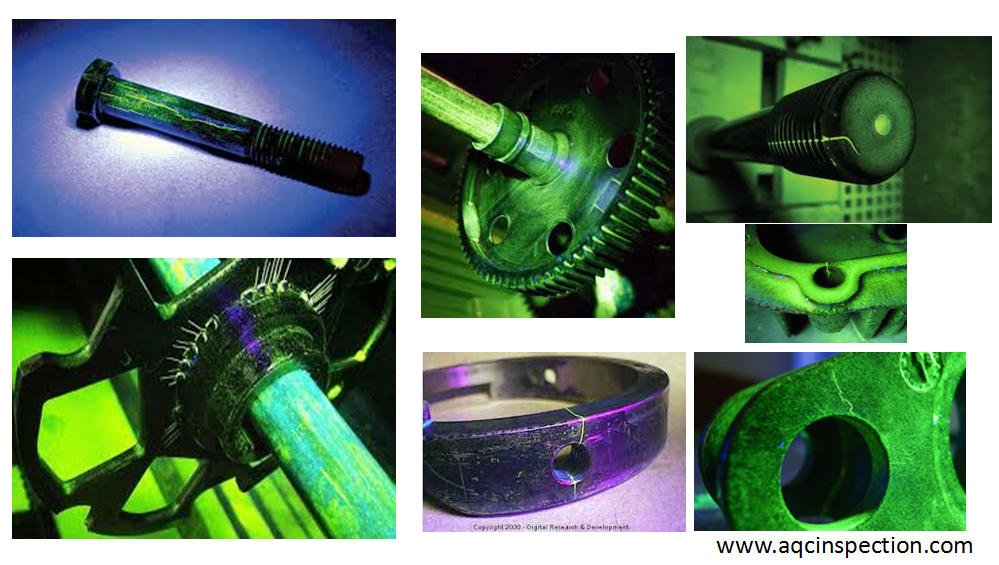

Magnetic Particle Testing (MPI):

1) MPI Electromagnetic yoke

2) Portable MPI machine – with prod cables and Wire wrap cables

3) Head shot machine of capacity 2000 Amps ( if required)

4) Pie gauge , CB strip.

5) Central conductor rod

6) Ketos ring

7) dead weights 4.5kg, 18.1 kg /21 kg

8) ASTM MPI test block

9) dry powder with puffer bulb

10) black wet particle, with spray can

11) Fluorescent lamp

12) wet fluorescent particle,

13) UV light intensity meter , Lux meter

14) Defective samples for MPI

15) Wire contrast paint aerosol cans

Liquid Penetrant Testing LPT :

1) Penetrant can (visible & fluorescent)

2) Cleaner

3) Developer

4) defect specimens

5) Fluorescent lamp

Reach us https://aqcinspection.com/training/ or call 8668082413 for sales or purchase of NDT equipments, consumables and accessories.

Visit our technical and career updates at our Blog site https://advancedqualitycentre.blogspot.com . or https://ndtcenter.blogspot.com

Thanks for this post...Eiwaa Group of Pressure Testing Services for Understanding operational pressure limits can be essential, which is why we utilize specialized pressure and collapse testing methods to solve our clients’ most complex environmental challenges.

ReplyDeleteHydro Testing Services

Storage tank survey

Thanks for this post..Eddy Current Testing method is widely used to detect surface flaws, to sort materials, to measure thin walls from one surface only, to measure thin coatings and in some applications to measure case depth. This method is applicable to electrically conductive materials only.

ReplyDeleteWater bag rental in Saudi

Tank Calibration Services