Ultrasonic testing Couplants

A study on the couplant effects in contact ultrasonic testing.

The primary purpose of a couplant is to provide a suitable sound path between the transducer and the test surface.Ultrasonic Testing couplants usage can be seen here

A couplant must effectively wet or totally contact both surfaces of the transducer and the test part.

- The couplant must exclude all air from between the surfaces as air is a very poor conductor of sound.

- The couplant fills in and smoots out irregularities on the surface of the part.

- The couplant aids in the movement of the transducer over the surface in contact testing.

- The practical couplant must be easy to apply and easy to remove. It must also be harmless to the part surfaces.

How to Pick the Right Ultrasonic Couplant for Your Application?

Oil or water mixed with Glycerin (2 parts water and 1 Part glycerin) are commonly used couplants. Even wallpaper paste has advantages as couplant.

Heavier couplants, such as Grease or heavy Oil can be used on rough or vertical surfaces.

Specially formulated liquid and paste couplants are also available from ultrasonic equipment manufacturers.

In circumstances where the use of liquids or paste is undesirable, thin rubber or rubber-like materials may be used.

In all cases the couplant should be as thin as possible, if the couplant is excessive, it may act as a wedge and alter the direction of the sound beam.

Why we need couplant in ultrasonic testing

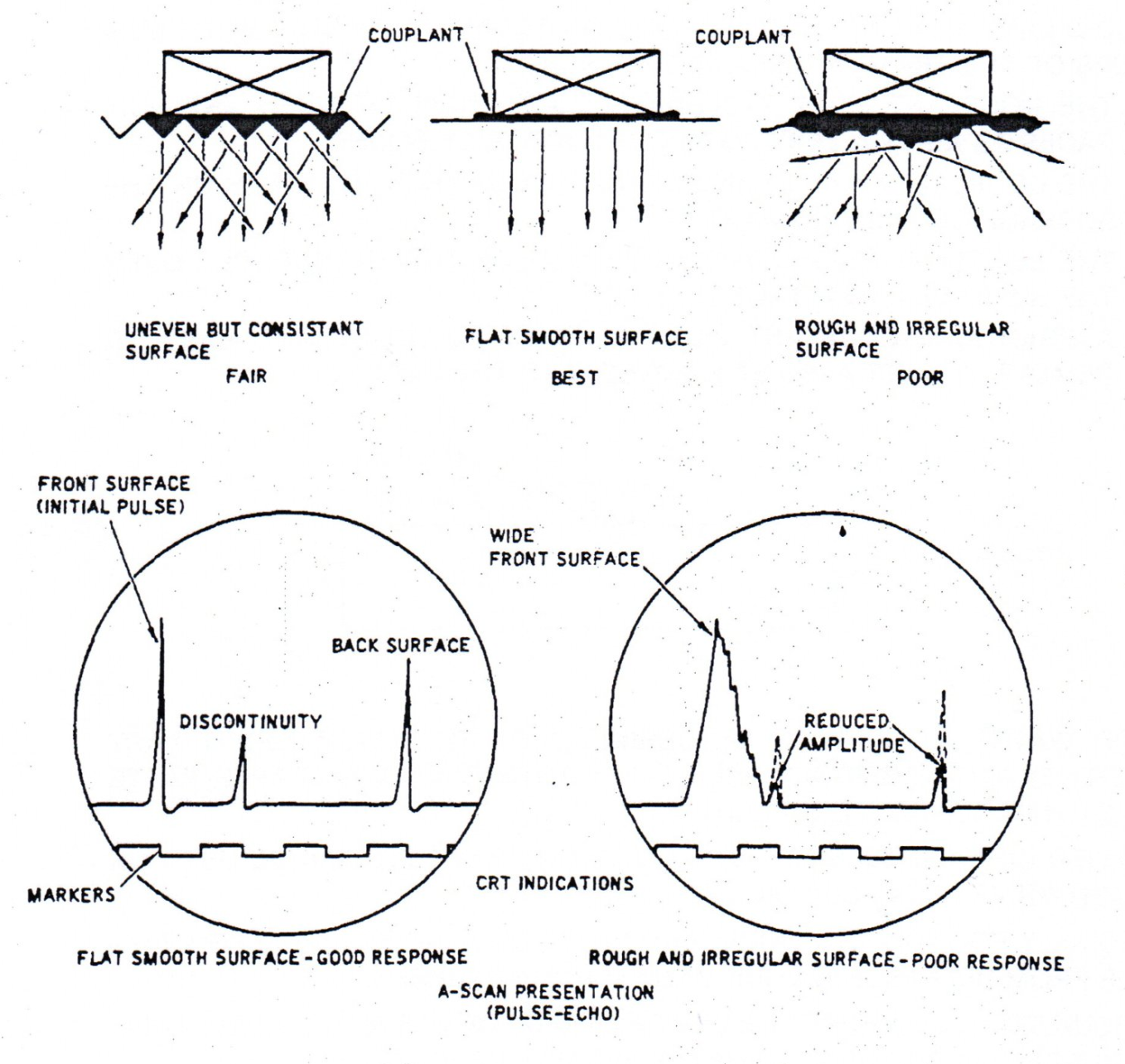

The surface of a test specimen can greatly affect ultrasonic wave propagation

Rough surfaces can cause undesirable effects such as reduction of discontinuity and back surface amplitudes due to distortion of wave directive.

What Ultrasonic Testing Couplant Should You Choose?

| Smooth Surface | Water, Oil, Gel |

| Medium Rough Surface | Oil, Gel |

| Rough Surface | Grease |

Ultrasonic Couplants – List

- Water

- Oil (ex. Motor Oil)

- Gel

- Starch water

- Grease

For more information and trainings for NDT, courses on NDT, we have our training institute open to all, visit us at https://aqcinspection.com/training/

Also know more about other NDT methods in our blog sites.https://advancedqualitycentre.blogspot.com . https://ndtcenter.blogspot.com our website https://aqcinspection.com/news-events/ for many more blogs

Comments

Post a Comment