Visual Testing in NDT (Non destructive testing)

Visual Testing in NDT:

Visual Inspection is method of visually inspecting the material for deciding the acceptablility of the material.

Infact it is the very first inspection method in Non Destructive Testing methods.

Sometimes the Visual Inspection is carried out with aid of additional Instruments and Devices such as Measurement tools & Vision aids.

What are essentials for visual Inspection ?

- Human Eye

- Lighting

- Acceptance Criteria

- Measurement Devices

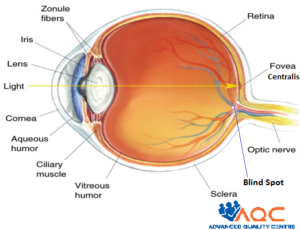

Human Eye

So in order to make sure the very essential instrument (EYE) is working properly , it is essential to investigate and make sure, it works properly.

So a Visual Acuity Test is recommended Yearly, by most of the standards

- Visual Acuity commonly referred to as clarity of Vision.

- It is dependent upon optical and neural factors.

i.e., (i) the sharpness of the retinal focus

(ii) the health and functioning of retina

(iii) the sensitivity of the interpretative faculty of the brain.

Vision Problems

- Glaucoma (increase in fluid pressure)

- Myopia (Near Sightedness)

- Hyperopia (Far Sightedness)

- Astimatism (Blurry Images & stretched out )

- Presbyopia (Age related condition, less abilty to focus close objects – aged lens)

- Conjunctivitis (Pink eye)

Eye Tests

- Jaeger’s Test J-1(Long Distance 6m)

- Jaegers Test J-2 (Short Distance 300mm)

- Snellen chart (Visual Acuity)

- Ishihara Test (Colour Discrimination)

- Grey Test ( Different shades of grey)

Lighting

- Natural

- Artificial – Incandescent, Fluorescent, Arc Lighting, LED

Measurement of Light

- 1) Newton’s inverse Square law

E= I / d²

- 2) Lambert’s Cosine Law

E = I cos Ø

Combination of both laws are used to measure the light requirement stated in the standards

Factors affecting the Visual Testing

- Surface Condition of material

– Cleanliness

– Colour

– Texture

- Physical Condition of material

– Specimen condition (coatings)

– Shape

– Size

– Temperature

Equipments

- Torch light

- Magnifier

- Mirrors

- Boroscope

- Fiberscopes

and lot more

Inspection Instruments

- Steel Rule

- Flexible Rule / Measuring Tapes

- Laser Measurement

- Vernier Calipers

- Micrometer

- Height gauges

- CMM

- Hi-Lo Gauge

- Depth Gauge

- Bore Dial Gauge

- Go-NoGo gauge (Plug, Ring)

- Dumpy Level

- Theodolite Total Station

Welding Gauges

- Bridge-Cam Gauge

- AWS weld Gauge

- Taper Gauge

- V-WAC Gauge

- Fillet weld Gauges

An Non Destructive Testing training Institute shall have Samples of all defects , which can be seen visually for familiarization of defect identification- Advanced Quality Centre , Coimbatore, NDT Training Institute for NDT Courses and Certification https://aqcinspection.com/training/

To learn more on NDT training in Coimbatore, NDT courses in coimbatore and Training Institute for specific ndt methods, feel free to contact us at https://aqcinspection.com/training/ and for services

Visit our technical and career updates at our Blog site https://advancedqualitycentre.blogspot.com . https://ndtcenter.blogspot.com our website https://aqcinspection.com/news-events/ for many more blogs

Comments

Post a Comment