ThermographyTesting – NonDestructive Testing Method

ThermographyTesting – NonDestructive Testing Method that involves visualization of heat radiations from an object and the method is a non contact inspection technique, .

It is also simply called as IR – Infrared Thermography, Thermal Imaging technique or Thermography.

Principle of Infrared Thermography Testing.

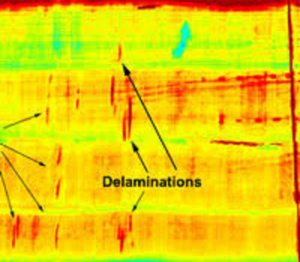

Infrared Thermography Sensors capture Infrared radiation from any object which is above absolute zero temperature (-273.15°C), and displays on screen as -heat distribution images, any defective areas emits more heat due to more heat distribution around the defects.

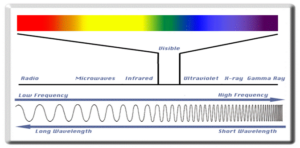

What is Infrared Wave?

Infrared are Electromagtic Radiation similar to Light Radiation, but are not visible to human eyes , becauses of their longer wavelength, the wave length of which is longer than Red (i.e 700 nm) is called Infra Red( i.e Inferior Frequency than Red Light),

Amount of Infrared Radiation captured is equal to the heat dissipated from that area, therefore the IR cameras can be used to capture images of heat distribution.

Thermography can be classified into different types as below

- Passive Thermography

- Active Thermography

- Flash Thermography

- Vibro Thermography

Passive Thermography.

It involves scanning the Component during its operation or Immediately after operation (ex. Running motor shaft) , It does not requires an external Heat source for heating, it uses the heat heat generated in the material during its operation.

Active Thermography.

The method requires an external heat source to heat the component and monitors the flow of heat inside the material.

Flash Thermography

Uses flashes of light , to identify the discontinuities that obstruct the flow of heat inside the material.

Vibrotheremography

This method uses a acoustic sound source, and a hermography sensor to detect the heat distribution inside the material, the acoustic sound vibration causes more heat at the edges of cracks due to friction during vibration.

Applications of Thermography:

The Infrared Thermography has vast applicable fields,

- Medical

- Security Screening

- Forensic Sciences

- Electrical Connections and instrumentation

- Civil Stuctures

- Rotary Equipments

- Loaded Structures

- Automobile industry

- Aerospace Structures and More……

To learn more on NDT training, NDT courses and Training Institute for specific ndt methods, feel free to contact us at https://aqcinspection.com/training/, or people located in Coimbatore feel free to visit us for free demonstrations.

Visit our technical and career updates at our Blog site https://advancedqualitycentre.blogspot.com . https://ndtcenter.blogspot.com our website https://aqcinspection.com/news-events/ for many more blogs to learn more.

Comments

Post a Comment