Penetrant testing principle and advantages

›Penetrant Testing is one of the effective method for detecting surface flaws,.

›It can be used on Metals, non-metals, plastics, ceramics & Glass.

›Not suitable for Porous materials such as wood, bricks, concrete, & other non graded castings, sponge

Qualification of Examination Personel

- ›Able to read a Jaeger Type No. 2 Standard Chart at a distance of not less than 12 in. (300 mm),

- ›Should be capable of distinguishing and differentiating contrast between colors used.

- ›These requirements shall be checked annually.

- ›Should clear the Examinations with percentage stated in ASNT SNT-TC-1A

Basic Principle

›Capillary Action

– Low surface tension fluid( dye) penetrates in to clean and dry defects open to the surface.

Advantages of PT

- ›High sensitivity to small surface discontinuities.

- ›Vast application -metallic and nonmetallic, magnetic and nonmagnetic, and conductive and nonconductive materials may be inspected.

- ›Large areas and large volumes of parts/materials can be inspected rapidly and at low cost.

- ›Parts with complex geometric shapes are routinely inspected.

- ›Indications are produced directly on the surface of the part and constitute a visual representation of the flaw.

- ›Aerosol spray cans make penetrant materials very portable.

- Penetrant materials and associated equipment are relatively inexpensive.

Disadvantages of PT

- ›Only surface breaking defects can be detected.

- ›Only materials with a relatively nonporous surface can be inspected.

- ›Pre-cleaning is critical since contaminants can mask defects.

- ›Metal smearing from machining, grinding, and grit or vapor blasting must be removed prior to LPI.

- ›The inspector must have direct access to the surface being inspected.

- ›Surface finish and roughness can affect inspection sensitivity.

- ›Multiple process operations must be performed and controlled.

- ›Post cleaning of acceptable parts or materials is required.

- Chemical handling and proper disposal is required.

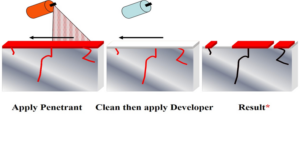

General Steps:

- Pre- Cleaning

- Apply Penetrant

- Dwell Time

- Excess Penetrant Removal

- Apply Developer

- Developing time

- Indications

- Interpretation

- Report

- Post Cleaning

For any further information about Non Destructive testing , for material testing service, third party inspection service or training and certification for Non Destructive Testing Methods visit https://aqcinspection.com/

Visit our technical and career updates at our Blog site https://advancedqualitycentre.blogspot.com . https://ndtcenter.blogspot.com our website https://aqcinspection.com/news-events/ for many more blogs to learn more.

Comments

Post a Comment