Welding Inspections- All you need to know about Metals

Welding is a process of joining similar metals, i.e. Metals with same base content and similar properties or melting point.There are different types of welding methods based on the process of welding. Generally it involves heating of the metal and fusing them, with or without additional filler metal.

The content below answers your questions:

- What are the types of Base metals?

- What is Carbon Steel and what is Alloy Steel?

- What is purpose of alloying element in steel?

- How are steels classified?

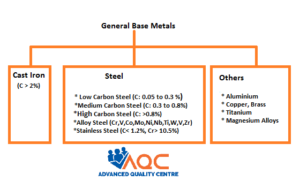

Different Base metals in general industry are :-

- Steel:

- Low Carbon Steel – C 0.05 to 0.3 % (ex: AISI 1005, 1008 etc)

- Medium Carbon Steel – C 0.3 to 0.8 %

- High Carbon Steels – C > 0.8 % (ex. A 36)

- Alloy Steel – (Cr, V, Co, Mo, Ni, Nb, Ti, W, V, Zr etc.)

- Stainless Steel (ex: SS304, SS 316 L, etc)

- Cast Iron – C >2%

- Aluminum

- Copper, Brass

- Titanium

- Magnesium Alloys

Why is Alloying Element added in steel?

Alloying elements are added to achieve a specific property for the steel. Different alloying element has different characteristics. The characteristics of the elements are given below:

Effects of Alloying Elements:

- Carbon (C) – Strength

- Chromium (Cr) – Corrosion Resistance

- Manganese (Mn) – Toughness

- Molybdenum (Mo) – 1% is for Creep Resistance

- Vanadium (V) – Strength

- Sulphur (S) – Impurity

- Phosphorus (P) – Impurity

- Silicon (Si) – Deoxidizer

- Nickel (Ni) – Low Temperature Applications

- Copper (Cu) – for Weathering Steels

- Titanium (Ti) – Grain Refiner, for micro alloying element (Strength & Toughness)

- Aluminum (Al) – Grain refiner, <0.008% deoxidizer + Toughness

- Niobium (Nb) – Grain refiner, for micro alloying element (strength & Toughness)

For more information of Materials , Testing, Welding Inspections, Welding Procedure WPS, Welder Certification, Non Destructive Testing, NDT, and QC Courses feel free to reach us at https://aqcinspection.com/ or call 0422 4342244, 9489342244 .

Visit our technical and career updates at our blog centre Visit our Blog site https://advancedqualitycentre.blogspot.com or https://ndtcenter.blogspot.com our website https://aqcinspection.com/news-events/ for many more blogs to learn more.

Comments

Post a Comment